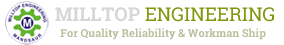

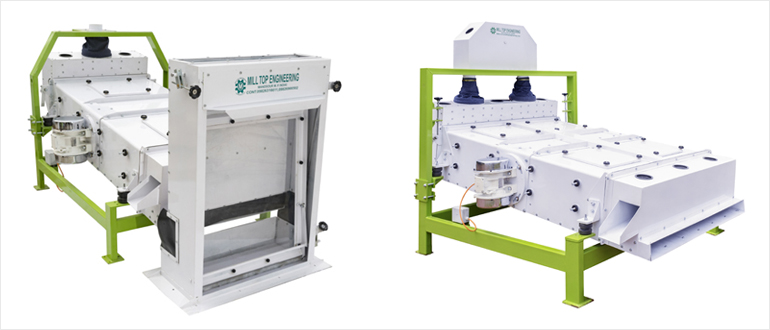

We are manufacturing a wide range of Vibro Screen Separator these vibro screen separator are fabricated using high grade raw material & are can high perfomance efficiency easy of use & durability available in standered specification . our vibro separetor available in 2 dack screen and 3 dack screen.

| Model | Power | Capacity in Wheat |

| MVS2-100/200 | (0.37 x 2) kw | 4 t/h |

| MVS3-100/200 | (0.37 x 2) kw | 4 t/h |

| MVS2-150/200 | (0.37 x 2) kw | 6 t/h |